KOA Speer – Fundamentals of a Resistor

What is a resistor?

To understand the function of a resistor, it’s important to understand Ohm’s Law.

Ohm’s law states that the current through a conductor between two points is directly proportional to the voltage across the two points.

Stated another way, Ohm’s Law means voltage = current x resistance.

If the voltage is E and the current is I, the following relationship holds.

| Ohm’s law : E=I x R |

The following relationships also hold:

Current = voltage/resistance (I = E/R)

Resistance = voltage/current (R= E/I)

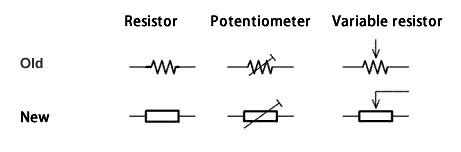

“R” represents the coefficient of proportionality and is called resistance (electrical resistance). It is the quantity symbol and Ω (ohm) is the unit symbol. The circuit symbol is as shown in the following figure.

Resistor Circuit Symbols

When the electrical resistance is high, it is difficult for the current to flow, and when the electrical resistance is low, it is easy for the current to flow. Using this phenomenon, the resistor, as an electronic component, provides constant current flow through a circuit or current adjustment as needed. Resistors are also used to reduce or divide voltage.

Therefore, resistors along with capacitors and inductors (coil) are the major passive components, which are essential basic components for electronic circuits.

Construction of a Resistor

Resistors are basically constructed using four elements – a base substrate, a resistive element, terminal and a coating.

Base substrate:

Holds resistive body and terminals

Alumina-based insulators are the most commonly used base substrate. Materials suitable for the application are selected as the base substrate of the resistor (Based on thermal conductivity, thermal expansion coefficient, mechanical strength, etc.).

Resistive element:

Determines basic characteristics and performance of the resistor

Electrical resistanceThe electrical resistance of the conductor is given by the following formula.

Electric resistance R=ρ x L/S [Ω]

- Cross-sectional area [cm2]: S

- Length [cm]: L

- Specific resistance of material [Ω x cm]: ρ

Resistance & T.C.R. of Major Metals

| Metals | Symbol | Electric resistance (μΩ・cm) |

T.C.R. (10-6/K) |

|---|---|---|---|

| Gold | Au | 2.4_ | 4,000 |

| Silver | Ag | 1.62 | 4,100 |

| Platinum | Pt | 10.6_ | 3,900 |

| Palladium | Pd | 10.8_ | 3,700 |

| Nickel | Ni | 7.24 | 6,700 |

| Tin | Sn | 11.4_ | 4,500 |

| Bismuth | Bi | 120___ | 4,500 |

| Tantalum | Ta | 15.0_ | 3,500 |

| Iron | Fe | 9.8_ | 6,600 |

| Copper | Cu | 1.72 | 4,300 |

| Nichrome | Ni-Cr (80:20) | 108___ | 100 |

| Manganin | Cu-Mn-Ni | 40___ | -5~+10 |

Terminal:

Electrically and mechanically, it connects the resistor and the board (circuit pattern).

The electrical connection point of the resistor, where voltage and current are applied. The structure and material are configured so that it does not affect the characteristics of the resistor.

Select a resistor with a terminal structure and shape suitable for the mounting method. Surface mount components (SMD) are now mainstream in order to improve the mounting density and reduce the mounting cost.

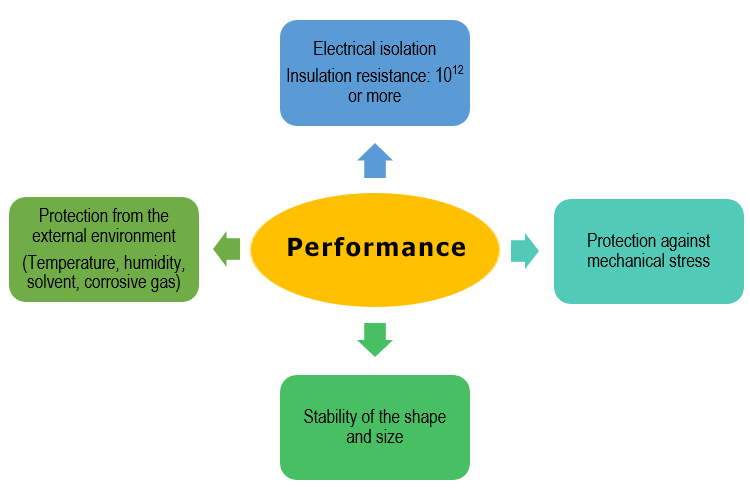

Coating:

Protects the resistive element and base substrate from the ambient air and mechanical stress

| Coating Material | |

|---|---|

| Organic material | Inorganic material |

|

|

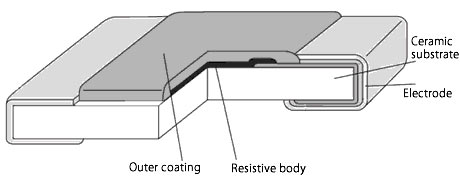

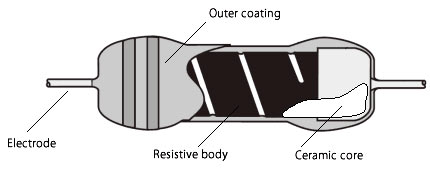

Typical Resistor structure

- Surface Mount Flat Chip Resistor

- Lead Type Resistor(film type)

Types of Resistors

There are various classifications or types of resistors depending on the combination of function, shape, resistive material, and application.

Categorized by function, there are three types of resistors:

- Fixed Resistors – used in an electric circuit (more detail about this type of resistor below)

- Trimmer Potentiometers – to adjust a circuit

- Variable Resistors – used as a radio volume by changing the resistance.

Fixed Resistors

Fixed Resistors are divided into surface mount type (without lead wire) and leaded type (with lead wire). Surface mount type includes rectangular type and cylinder type. In addition, division goes further depending on the sealing material: resin mold type and ceramic case type.

Resistive Element Materials include: carbon film, metal film consisting mainly of nichrome, metal oxide film, metal glaze composites consisting of metal oxide and glass; elements using metal plate, metal wire or metal foil; and solid type consisting of metal oxide ceramics.

Characteristics of Resistors include those with highly accurate resistance tolerance and temperature characteristics, those that withstand high voltage and surge, those with large fluctuations in resistance value depending on temperature, and those that also have a fuse function.

It is important to select an optimal combination out of available options according to the purpose of the application when selecting a resistor.

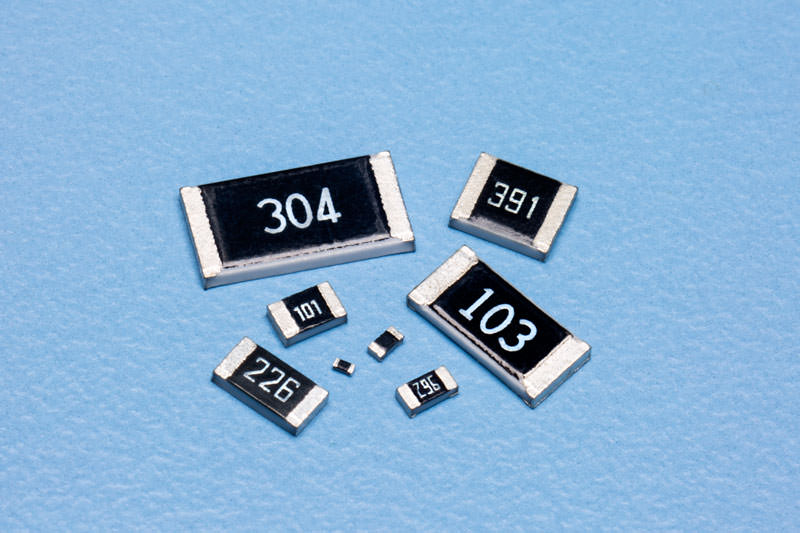

SURFACE MOUNT CHIP TYPE FIXED RESISTORS

Resistors with terminals that have been treated for soldering or bonding and do not have terminal wires (lead wires). They can be divided into rectangular type and cylindrical type. Five types depending on the resistive material are shown below.

- Rectangular type – 1. Metal glaze film type, 2. Metal film type, 3. Metal plate type

- Cylindrical type – 4. Carbon film type, 5. Metal film type

Among them, the metal glaze film type accounts for the majority of the market in terms of cost, downsizing, and ease of mounting. Some statistics show that more than 90% of chip fixed resistors are metal glaze film type.

The trend of downsizing is remarkable in the chip type, and the demand has been increasing for 1005 size (1.0 mm x 0.5 mm) and 0603 size (0.6 mm x 0.3 mm) for the rectangular type. The adoption of 0402 size (0.4 mm x 0.2 mm) has been advancing for mobile communication devices such as mobile phones and smartphones.

Rectangular Type Chip Fixed Resistors

This type can be roughly divided into thick film metal glaze type and thin film metal type. Mass production is mainly on thick film type. The thick film type features excellent mount ability and environmental resistance, whereas the thin film type features small resistance tolerance, small T.C.R. and low current noise. In particular, the T.C.R. of the thick film type is around 25×10-6/K, while that of the thin film type is as small as around 5×10-6/K, making its resistance value stable over time.

The size of rectangular type resistor has been standardized in 0402, 0603, 1005, 1608, 2012, and 3216 (mm code). The demand for 0403 size in particular is rapidly increasing among mobile communication devices. 0603, 1005, and 1608 size are widely used for applications in consumer products, industrial equipment and automotive. High power type has 3216, 3225, 5025, and 6331 size in the lineup. Recently, wide terminal types that provide higher rated power compared to chip resistors of the same size, have been developed in 0510, 0816, 1220, 1632, 2550, and 3163 size.

Cylindrical Chip Fixed Resistors

Commonly known as MELF (Metal Electrode Leadless Face), a type of chip resistor with a structure of a general type axial lead resistor without the lead wire but with the metal plated cap attached to the electrodes at both ends. Its cylindrical shape and metal cap eliminate the concept of front and back, give excellent electrode and mechanical strength, and have precise structural dimension that achieves high precision in supplying and mounting of resistors. In addition, the metal film type is excellent in the resistance accuracy, T.C.R., and suppressing current noise.

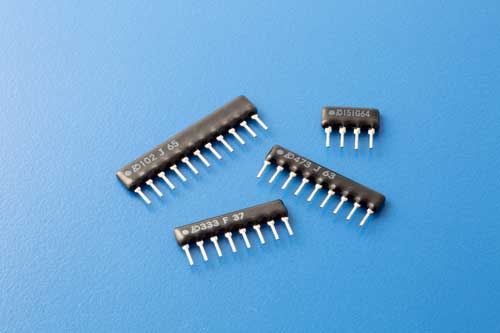

RESISTOR NETWORKS

Resistor networks in which two or more resistive elements are integrated and combined on an insulating substrate to form a single electronic component. Each element can be connected as necessary. An array is simply a continuous integration of resistors with two electrodes, while a network is an integration of formed circuit. The main applications are pull-up and pull-down resistors for digital circuits.

Resistor networks in which two or more resistive elements are integrated and combined on an insulating substrate to form a single electronic component. Each element can be connected as necessary. An array is simply a continuous integration of resistors with two electrodes, while a network is an integration of formed circuit. The main applications are pull-up and pull-down resistors for digital circuits.

Depending on the shape, they can be classified into SIP (Single Inline Package) type, DIP (Dual Inline Package) type, flat package type, and chip carrier type.

In the 1980s, when the production of carbon film resistors was the mainstay, the production volume of SIP type drastically increased to support high-density mounting. However, in the 1990s as mounting technology took a change to surface mounting, chip network resistors began to be used. In the past, network resistors were often used around logic ICs and parallel ports for I/O, but since the processing by microcomputers and use of serial buses for I/O have progressed, the demand of network resistors has been declining significantly.

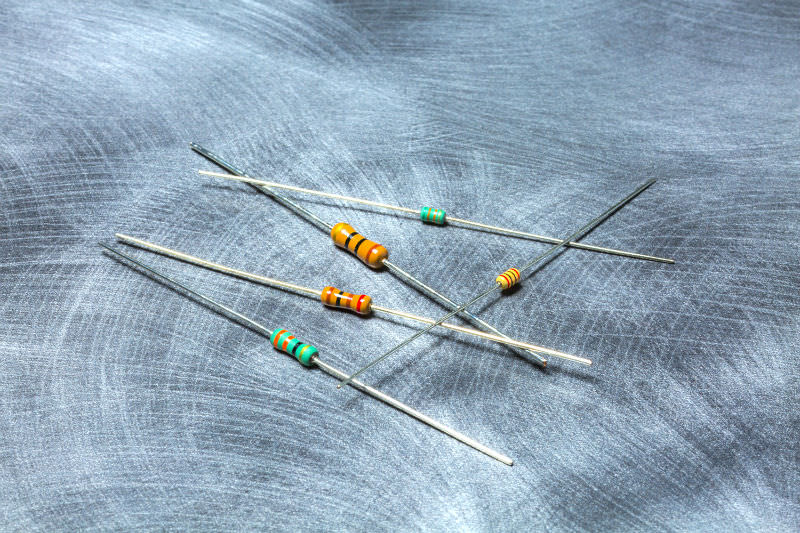

LEADED TYPE FIXED RESISTORS

Carbon Film Fixed Resistors

Fixed resistors with excellent pulse resistance that use a carbon film as a resistive element, and have long been the most popular resistor. In terms of electric power, 1/4 W and 1/2 W types are the most common in the marketplace. Small types such as 1/4W type of 3.2 mm x 1.9 mm size and 1/2 W type of 6.3 mm x 2.85 mm size are mainstream and widely used as general-purpose products.

Metal Film Fixed Resistors

Fixed resistors with a metal film as a resistive element, which provides small resistance tolerance, T.C.R., less aging variation, high accuracy, excellent stability and low current noise. The main applications include industrial equipment such as telecommunication and measuring equipment, as well as automobiles and sensor modules, which require the high precision for circuits to handle minute signals.

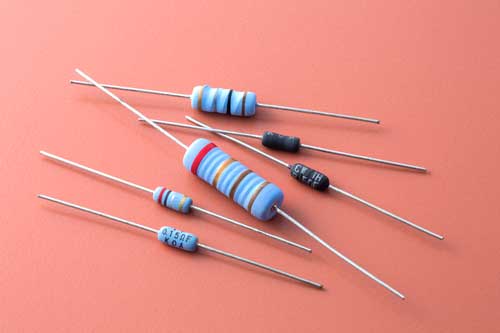

Metal Oxide Film Fixed Resistors

Fixed resistors with a metal oxide film as a resistive element, which provides high power rating in a small size (the smallest volume per rated power among all the resistors), and an excellent heat resistance. Low T.C.R. is achievable at a lower cost compared to power type metal film resistors. The main application is power supply circuit.

WIREWOUND FIXED RESISTORS

Fixed resistors with a metal resistive wire as a resistive element. It has excellent pulse resistance and heat resistance. Its low T.C.R. achieves the low current noise. On the other hand, it is difficult to obtain a high resistance value, and the winding structure makes it unsuitable for high-frequency circuits. Wirewound resistors are mainly used as a pre-charge resistor in power supply circuits. These resistors with low resistance are used for current sensing.

Reference:

・Almanac of Electronic Components 2019 (publicated by Chunichi-sha)

・Statistical data by “Ministry of Economy, Trade and Industry” in Japan

Terms and Definitions

- Nominal Resistance

- Designed resistance value usually indicated on the resistor.

- Power Rating

- Maximum allowable power at rated temperature. Some of our chip resistor arrays and networks specify the power rating for the entire package, as opposed to each element.

- Rated Ambient Temperature

- Maximum ambient temperature at which the power rating may be applied continuously. The rated ambient temperature refers to the temperature around the resistor mounted inside the equipment, not to the air temperature outside the equipment.

- Rated Terminal Part Temperature

- Maximum terminal part temperature of the surface mount resistor at which the power rating may be applied continuously. Includes the temperature rise by self-heat generation.

- Derating Curve

- Curve that expresses the relation between ambient temperature or terminal part temperature and the maximum allowable power, which is generally expressed in percentage.

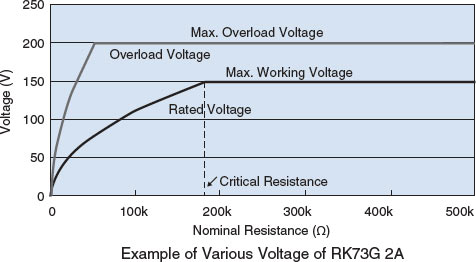

- Rated Voltage

- Maximum allowable D.C. or A.C. voltage, to be continuously applied to a resistor or a resistor element.

Rated Voltage (V) = √Rated Power (W) X Nominal Resistance Value (Ω)

Rated voltage shall be the calculated value or max. working voltage, whichever is lower. - Critical Resistance

- The maximum nominal resistance value at which the rated power can be applied without exceeding the maximum working voltage. The rated voltage is equal to the max. working voltage at the critical resistance value.

- Max. Working Voltage

- Maximum D.C. or A.C. voltage (rms) that can be continuously applied to the terminations of a resistor. However, the maximum value of the applicable voltage is the rated voltage at the critical resistance value or lower.

Maximum working voltage and rated voltage are calculated D.C. voltage based on rated power. Sine wave is assumed for the A.C. voltage so the peak voltage should be √2 times the maximum working voltage. When the waveform is not a sine wave, or when the resistance value exceeds the critical resistance, please contact us for the applicable peak voltage. - Overload Voltage

- Allowable voltage which is applied for 5 sec. according to the short time overload test. Overload voltage shall be 2.5 times of rated voltage or max. overload voltage, whichever is lower

- Maximum Overload Voltage

- Largest value of overload voltage

- Dielectric Withstanding Voltage

- A.C. voltage (rms) that can be applied to a designated spot between the electrode and the outer coating for one minute according to the proof test

- Temperature Coefficient of Resistance (T.C.R.)

- Relative variation of resistance between two given temperatures when temperature is changed by 1K, which is calculated by the following formula.

T.C.R. (×10−6 /K) = R−R0 × 1 × 106 R0 T−T0 R : Resistance value (Ω) at T

R0 : Resistance value (Ω) at T0

T : Measured test temperature (°C)

T0 : Measured base temperature (°C)